Infrastructure | NGI All News Access

Chesapeake Utilities Partners with CleanBay Renewables in Next Move to Bring RNG to Customers

Chesapeake Utilities Corp. (CPK), headquartered in Dover, Delaware with 240,000 customers from Florida, Ohio, Pennsylvania, and the Delmarva Peninsula across its subsidiaries, announced another partnership in the hopes of expanding renewable natural gas (RNG) options for its customers. This time, CPK is partnering with CleanBay Renewables Inc, an enviro-tech company focused on sustainable RNG production.

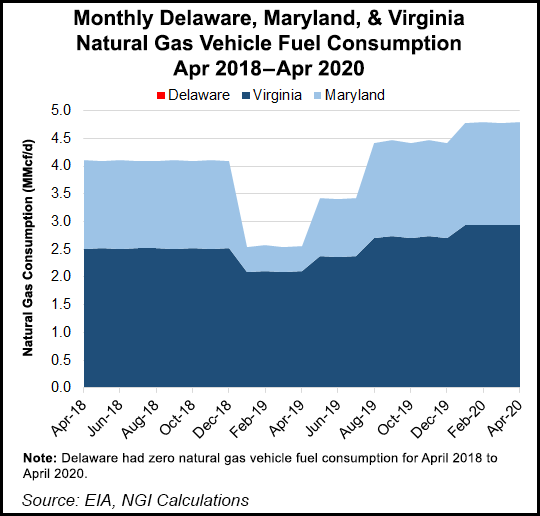

Through this arrangement, CPK plans to transport the RNG produced at CleanBay’s Westover, Maryland bio-refinery, to CPK’s natural gas infrastructure in the Delmarva region. The RNG produced will generate greenhouse gas (GHG) credits associated with vehicular usage, and bring Chesapeake Utilities the opportunity to provide additional RNG to the company’s Delmarva operations.

RNG produced at CleanBay’s facility will come to the market through the efforts of CPK and its subsidiaries — Eastern Shore Natural Gas Co. (ESNG), and Marlin Gas Services.

Marlin Gas will transport RNG using a virtual pipeline concept from the CleanBay facility to ESNG, then on to CPK’s interstate infrastructure pipeline, where it is to be distributed to end-users, including low-carbon, renewable vehicle fuel customers.

“Our process to turn poultry litter into renewable natural gas is a sustainable, environmentally friendly way to both positively influence our region’s poultry ecosystem and reduce U.S. greenhouse gas emissions for end use customers including powering vehicle fleets with clean, green energy,” said CleanBay Renewables’ Executive Chairman Thomas Spangler.

At least 150,000 tons of chicken litter will be recycled at the Westover bio-refinery annually. Through this repurposing, CleanBay estimates 765,000 MMBtu of RNG can be produced. This amount of energy is equivalent to the energy used by roughly 10,000 homes.

“Utilizing the renewable natural gas derived from processing excess poultry industry organics in the Delmarva region and transforming that into a carbon-negative sustainable energy source, supports our long-standing commitment to our customers and communities to invest in a resilient, environmentally-friendly and diverse energy supply,” said CPK’s President, Jeff Householder. “This is a win-win for the region as farmers on the Delmarva Peninsula also need an economical way to dispose of agricultural waste, prevent runoff into local waters, and enrich the soil to increase future agricultural production.”

The Westover facility is to be funded in part by a $200 million capital investment by CleanBay. Preparation for the facility is already in the works, with construction currently scheduled to commence later this year.

“The clean energy produced at each facility will reduce 550,000 tons annually of greenhouse gas emission equivalents (equal to removing 107,795 gasoline-fueled vehicles off the road)” said CleanBay CEO Donal Buckley

While CPK and its subsidiaries work to expand regionally, the company’s goal is to implement RNG directly into Chesapeake Utilities’ infrastructure in order to reduce regional GHG emissions.

Last month, CPK partnered with Bioenergy Devco (BDC), a developer of facilities that create renewable energy and soil products. BDC, which develops anaerobic digestion facilities in the Mid-Atlantic, recently entered into a 20-year agreement with Perdue Farms, giving it access to the poultry waste at facilities on the peninsula. Anaerobic digesters use naturally occurring microbes to break down food waste into biogas.

Similar to CleanBay’s future facility, the Bioenergy Innovation Center, the BDC’s anaerobic digestion facility in Delaware, would be used to process the organic material. Once refined into usable RNG, it would be distributed by CPK’s affiliates to natural gas customers.

© 2024 Natural Gas Intelligence. All rights reserved.

ISSN © 1532-1231 | ISSN © 2577-9877 |