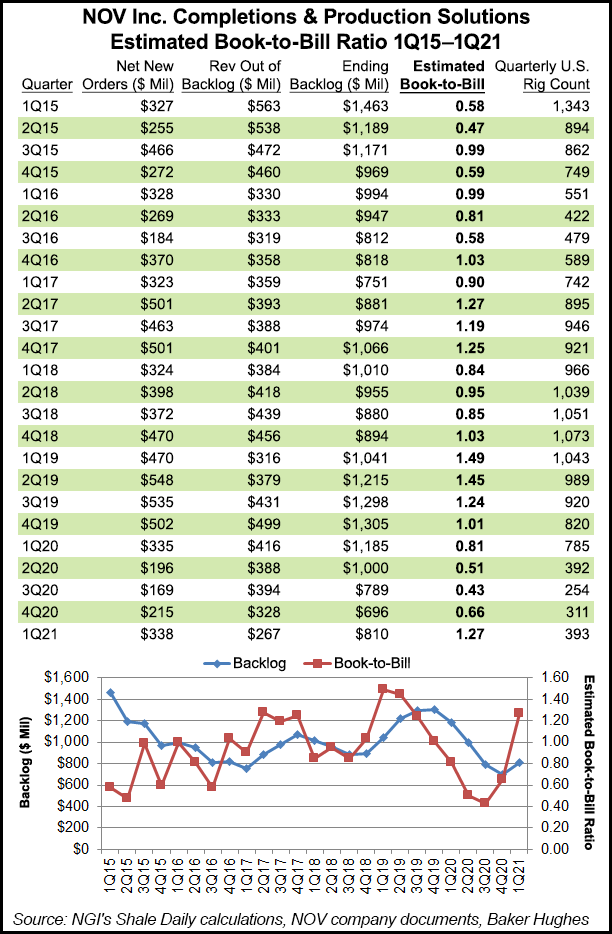

Houston-based NOV Inc. faced challenging conditions for its rig equipment and technology in the first quarter, but as activity in North America and overseas improves, business should improve going forward, CEO Clay Williams said Wednesday.

Williams, who held court to discuss the first quarter during an hour-long conference call, said the latest results reflected the “full impact of the shockwave” of 2020. Adding insult to injury, the first quarter “was further impacted by other factors,” he said.

“Severe winter weather and power outages in Texas and Oklahoma led to 63 NOV facilities being shuttered for a week or more,” he told analysts. NOV had signaled in March that the February freeze would weigh on first quarter results.

“Additionally, new pandemic control...