Energy Transition | NGI All News Access

Dow, in Decarbonizing Mode, Considers Small-Scale Nuclear to Power Gulf Coast Facility

© 2024 Natural Gas Intelligence. All rights reserved.

ISSN © 1532-1231 | ISSN © 2577-9877 |

Markets

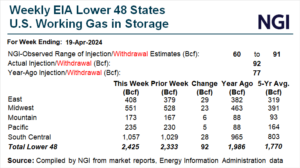

Natural gas futures tried to shake off a stronger-than-expected government inventory print Thursday but settled lower as benign weather and LNG hiccups weighed. At A Glance: EIA reports 92 Bcf injection West Texas cash flips negative Freeport LNG stays down Following a nearly 16-cent decline, the May Nymex contract settled down 1.5 cents day/day at…

April 25, 2024By submitting my information, I agree to the Privacy Policy, Terms of Service and to receive offers and promotions from NGI.