Shell to Transform Skyline With 200 Structures As Pennsylvania Cracker Construction Gets Underway

Major equipment and structures will be erected over the next year for Shell Chemical Appalachia LLC’s multi-billion dollar ethane cracker plant in western Pennsylvania, company officials said Thursday at the Shale Insight conference in Pittsburgh.

For years, the company has been focused on site preparation, clearing 400 acres of land where a zinc smelting plant once stood. After Shell decided to move forward with the project last year, crews have focused more recently on underground work for sewage, electricity and foundations. But that’s about to change as the company is close to starting construction on the 200 structures that will make up the plant and change “the whole skyline dramatically,” with the tallest at more than 300 feet, said Todd Whittemore, Shell’s polyethylene global technology manager.

Whittemore told the audience that the facility, under construction in Beaver County about 30 miles northwest of Pittsburgh, would be “self contained,” with its own natural gas-fired power plant, water treatment facility and a fully-staffed emergency response team. It is Shell’s first completely new site in the United States since the late 1960s, when it last built in Louisiana, he added.

The ethane cracker is just one part of a much larger complex that would also include polyethylene units to help make the pellets Shell plans to sell for plastics conversion, a cooling tower, a control building, offices and transloading facilities, among other things.

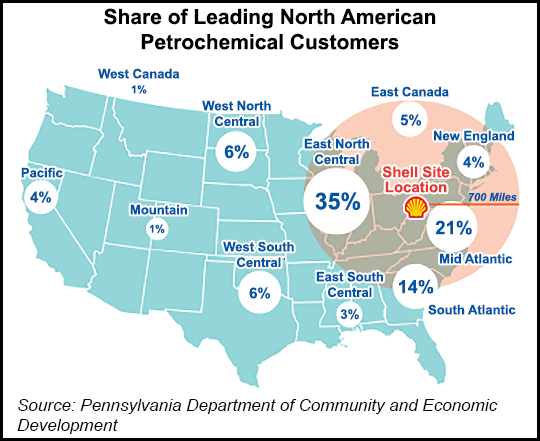

About 70% of the North American marketplace for polyethylene is within a 700-mile radius of the site along the Ohio River, said Shell Appalachia’s Business Integration Lead Michael Marr. Most of the market is primarily served by the Gulf Coast.

“I know that sounds like a very long distance, but when it comes to the way chemicals are sold and transported in North America, it’s actually quite close,” he said. “We’re definitely location-advantaged both from a supply standpoint to the Marcellus and Utica formations, as well as from the customer standpoint. That double location advantage is really what led us to the decision to invest here.”

Chemical, mechanical and civil engineers are expected to comprise about a quarter of the facility’s 600 full-time workers. Health, safety and environmental personnel positions are also expected to be a major part of the workforce to support Shell’s air, waste, water and compliance programs at the site, Environmental Manager Jim Sewell said. Pipefitters, electricians, boilermakers and technicians to operate the facility are expected to round out the full-time staff.

Pittsburgh Regional Alliance President David Ruppersberger said he expects indirect jobs to be created throughout Ohio, Pennsylvania and West Virginia. For example, Ruppersberger expects a large industrial gas company to create a facility to supply the plant with nitrogen. Continuing maintenance at the facility for turnarounds to take plant parts out of operation, replace them and repair other components is also expected to create indirect jobs.

The region is already home to some of the world’s largest plastics companies, but more plastics converters are expected to come to the area by the time the cracker enters service in the early 2020s. Ruppersberger said those facilities, however, only take about 18 months to build and enter service. They also require a smaller footprint and would make smaller regional investments.

“We do expect to see some of that located here, although there’s not really incentive for them to do that because we’re not going to see pellets for awhile,” he said. “The expectation is that sometime in the next two to three years, we’ll start to see more plastics manufacturing.”

Sewell said the facility has all its major permits for air quality, water discharge and wetlands. The only other major permit the company needs is one for its water treatment facility when it enters service. The company is still working to secure other minor permits for things like parking.

The cracker is designed to consume a little more than 100,000 b/d of ethane to produce 1.5 million metric tons of ethylene and 1.6 million metric tons of polyethylene per year. Shell has signed 10-20 year supply agreements with 10 Appalachian natural gas producers. The company is currently purchasing rights-of-way for a pipeline system it plans to construct to feed the facility, a process Whittemore said remains on track.

About 1,035 people attended the annual Shale Insight conference, which culminated in the Shell team’s presentation on the final day of the event. The company played a video to describe the facility in detail, which stopped activity on the exhibit floor and had the audience’s full attention as all eyes seemed trained on the display screen. Shell’s decision to build the facility marks the first time in more than 20 years that such a plant has been built in the United States outside of the Gulf Coast.

© 2024 Natural Gas Intelligence. All rights reserved.

ISSN © 1532-1231 |