Infrastructure | NGI All News Access | Shale Daily

Sasol’s Lower 48-Fueled Lake Charles Chemicals Project Nearing Completion

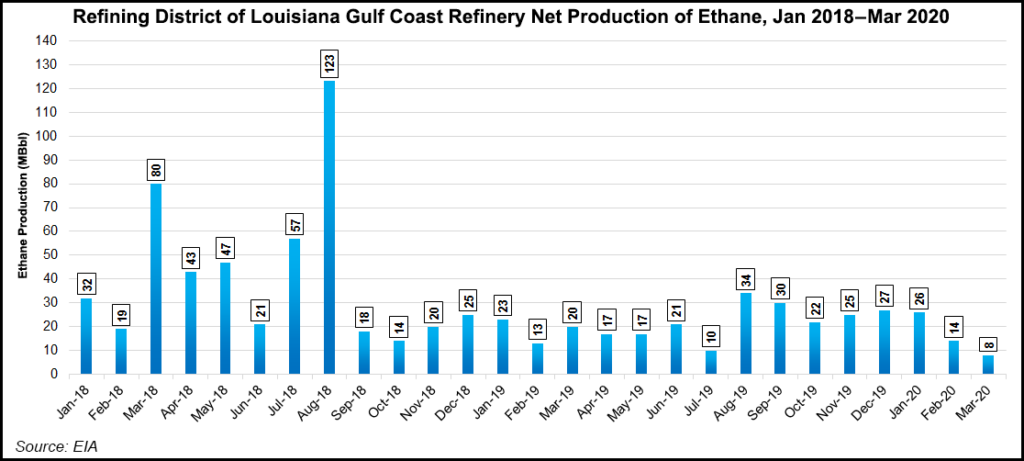

Fueled by abundant and low-priced Lower 48 natural gas and oil, Sasol Ltd. is in sight of completing a massive ethane cracker complex in Lake Charles, LA, by the end of the year.

After facing budget overruns and a delay of the world-scale Lake Charles Chemicals Project (LCCP), the complex would triple the South African operator’s chemical production capacity in the United States and build its positions in the growing global chemical markets.

The deadline to finish by this fall is coming into sharper focus after two more chemical units ramped up this month.

At the heart of the LCCP is the cracker, designed to produce 1.5 million tons/year, using Lower 48 supply. The complex also is to include six chemical manufacturing plants.

The Ziegler alcohol unit began operating earlier this month, and the Guerbet alcohol unit went online a few days ago, bringing the online capacity of the LCCP’s specialty chemicals units to 100% and total online nameplate capacity to 86%.

“The beneficial operations of these LCCP facilities progresses Sasol’s seven-unit U.S. Gulf Coast mega-project to the cusp of completion,” said CEO Fleetwood Grobler. “The additional capacity strengthens Sasol’s leadership position in the specialty alcohol and alumina markets, which is core to the company’s chemicals growth strategy.”

The Ziegler unit is an extension of the existing Ziegler plant in Lake Charles and is considered the largest of its kind in the world, adding nameplate capacity of 173,000 tons/year of alcohol and 32,000 tons/year of alumina. Guerbet has a nameplate alcohol capacity of 30,000 tons/year.

LCCP’s seventh and final unit, a low density polyethylene, or LDPE, plant, is on track for beneficial operations by the end of September.

The Lake Charles investments, which include additional ethoxylation capacity that began operation in January, as well as the startup of an ethoxylation unit in Nanjing, China last year, “strengthens our existing asset base,” said Executive Vice President Brad Griffith, who oversees the chemicals business.

When the LCCP was sanctioned six years ago, Sasol had estimated it would be ready in 2018 at a cost of about $8 billion. In 2017, following a review of its global projects, the U.S. line-up was reconfigured and Sasol scuttled what would have been the largest U.S. natural gas-to-liquids project that at the time was underway near Lake Charles.

At the end of May, the LCCP capital expenditures were tracking at $12.8 billion, Sasol said. Presciently, considering the downturn in global demand from the pandemic, Sasol had said in 2017 it was winding down some projects because of the “volatile external environment and structural shift to a low oil price environment.”

To date, Sasol said the LCCP has generated more than 800 full-time manufacturing jobs, with up to 6,500 people on site during construction, with nearly $4 billion spent on construction for Louisiana businesses and nearly $200 million paid in local and state taxes.

© 2024 Natural Gas Intelligence. All rights reserved.

ISSN © 2577-9877 | ISSN © 2158-8023 |