Marcellus | E&P | NGI All News Access | NGI The Weekly Gas Market Report | Utica Shale

Push to Optimize Results During Downturn Led to Eclipse’s Behemoth Utica Well

While the past two years have been marked by declining profits, drilling activity and workforces for the oil and gas industry, innovations have underscored the downturn as well, with producers relying on technology to help shore-up their balance sheets.

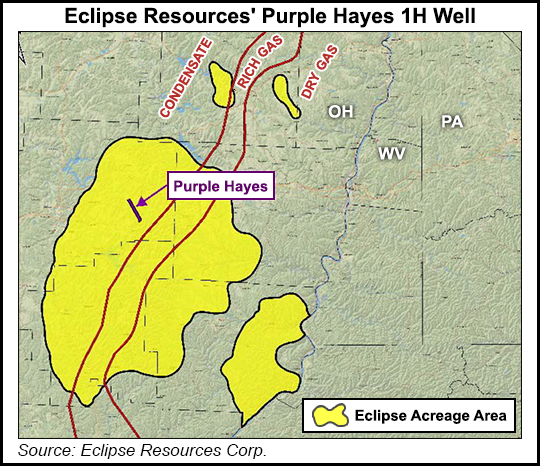

One example is Eclipse Resources Corp.’s Purple Hayes 1H well in Ohio’s Utica Shale, completed with an 18,544 foot lateral and 124 stages, setting what’s likely a record for the longest onshore lateral in the United States and possibly the world (see Shale Daily, May 5).

The Purple Hayes was drilled in the condensate window in Guernsey County, and at a cost of $15.8 million it wasn’t cheap. According to Eclipse’s type curve summary, a 10,000-foot lateral in the condensate window costs about $9 million; the same length in the dry gas window has run the company about $10 million. Ultimately, Eclipse management believes it can drill even longer wells with a goal of reducing drilling and completion costs per foot and improving well economics.

Eclipse said the longer laterals should drive down finding and development costs by 20-30% in the condensate area and improve well returns by 35-70%.

“In the current low commodity environment, operators like Eclipse are targeting their core acreage and remain focused on optimizing development with longer laterals and shorter spacing,” said Nine Energy Service Inc. Vice President of Completions Technology Nick Pottmeyer. “Longer laterals are proving to be a more effective way to develop acreage. Increased well costs to drill [deeper] can be justified by the improved production ranges and return on revenue.”

Privately owned Nine Energy, an oilfield services company that offers completion, wireline and cementing solutions in North America, worked with Eclipse to design the plug and perforation system with well modeling software. The Purple Hayes was drilled in 18 days, and Nine said it took 23.5 days to complete without any unproductive time. Eclipse Completions Manager Kyle Bradford said the company knew there would be a “number of challenges” for the well, but management said the goal was to enhance the return profile of the Utica by determining the technical limits of lateral length in the liquids portion of its acreage.

CEO Benjamin Hulbert told financial analysts earlier this month during a call to discuss the first quarter results that management believes it can drill even longer laterals and said the techniques used in the Purple Hayes should translate well across the Ohio pure-play’s acreage.

“It’s pretty neat. And really, the way you look at this is this is three laterals back-to-back in one well,” said Pennsylvania State University’s Terry Engelder, geosciences professor and Appalachian Basin expert. “If you have a rock that’s strong enough so that it doesn’t collapse on the drill rod as you’re drilling it, that probably is the major parameter that limits the length of these wells. They are in a rock in the Utica that has the kind of strength to remain open to allow that distance for drilling.”

Engelder pointed to ExxonMobil Corp.’s Sakhalin 1-Project offshore far east Russia, which is widely thought to be the world’s longest extended-reach well. An ExxonMobil subsidiary drilled the Odoptu OP-11 well to a total measured depth (TMD) of 40,502 feet, setting what it said was a world record in 2011 with a horizontal reach of 37,648 feet, or more than seven miles.

The Eclipse well had a TMD of 27,034 feet. By comparison, in the onshore closer to the Purple Hayes, Antero Resources Corp. set a company record in the fourth quarter with its Nova Unit 2H Marcellus Shale well in Doddridge County, WV, which was drilled with a lateral of 14,024 feet.

Engelder said there’s a trivial difference between the distance of the Antero and Eclipse wells, but noted that the Utica is likely more conducive to extended reach laterals. In the Marcellus, he said the folds of the Appalachian Plateau make longer wells more difficult. There are more faults and rock beds dip.

“I think the geological sweet spot, in terms of why it was done in Guernsey County, is that the rock is probably less faulted and more flat lying,” Engelder said. “In other words, you can aim the drill right straight forward and expect to stay in the same horizon all the way and you don’t have to worry about crossing faults. I don’t think this can be done in some of the Marcellus because of those geological complexities.”

Eclipse has more than 100,000 acres in Noble, Guernsey, Monroe, Belmont and Harrison counties. Analysts have noted that it could face liquidity strains next year if natural gas prices don’t improve (see Shale Daily, March 3). After the Purple Hayes, the company said it would again idle its drilling program until late summer and it is currently curtailing volumes as it waits for better prices, factors that make well optimization an even higher priority for a company in its situation.

Beyond reduced drilling activity, workforce reductions and other cost-cutting measures, operators across the Appalachian Basin are finding more ways to manage through the downturn. Most of the basin’s leading producers have retreated almost exclusively to their dry gas acreage where low breakeven prices and prolific wells are being used to defend against low prices (see Shale Daily, April 7). Some operators are also reverting back to wider spacing to either save on land costs or pair longer laterals with more efficiently spaced wells to boost estimated ultimate recoveries and reduce interference (see Shale Daily, April 8).

Footage drilled in the Utica has grown exponentially since unconventional drilling began in the play about six years ago. In 2010, the average footage drilled per well was 3,883 feet, according to the Ohio Oil and Gas Association’s Debrosse Memorial Report, an annual analysis of drilling operations in the state. By last year, that number had increased to 12,336 feet, boosting the average initial production of gas for each well from 50 Mcf/d to 5.4 MMcf/d.

While the Utica might be a top candidate for extended reach wells like the Purple Hayes, Engelder said similar techniques could be on the horizon for other operators across the basin and around the country.

“The key is not in the completion techniques. I mean, once you have the well drilled and you put casing in place then the bore hole is stable and the completions are just the same,” he said. “I don’t think there’s anything different about completing a short versus a long well. The key is drilling it, that’s where things get different is the length of the well itself.”

© 2024 Natural Gas Intelligence. All rights reserved.

ISSN © 2577-9877 | ISSN © 1532-1266 | ISSN © 2158-8023 |