Infrastructure | NGI All News Access | NGI The Weekly Gas Market Report

Mississippi ‘Clean Coal’ Plant Likely to Burn Only Natural Gas

Mississippi Power Co.’s “clean coal” facility in Kemper County, MS, may end up only burning natural gas after state regulators took steps this week to prevent cost recovery for the “unproven” coal gasifier and carbon capture facilities.

The Mississippi Public Service Commission (PSC) on Wednesday instructed staff to develop “potential solutions” for protecting ratepayers from additional costs related to the experimental Kemper County Power Generation Facility, which has cost the subsidiary of Atlanta-based Southern Company $7.5 billion to develop as of April — well above the $4.3 billion approved for cost recovery.

The over-budget, first-of-its-kind facility is designed to produce synthetic gas (syngas) from locally mined lignite coal, which would be used to power a combustion turbine. The 582 MW Kemper facility should produce less greenhouse gas emissions than a comparable natural gas-fired plant by capturing at least 65% of its carbon dioxide (CO2) emissions. The CO2 could then be used for enhanced oil recovery, according to the utility.

The PSC staff was instructed to “remove risk from ratepayers for the lignite coal gasifier and related assets” at the Kemper facility. Regulators also called for “no rate increase to Mississippi Power Co. customers. The commission strongly encourages serious discussions leading to potential rate reduction, particularly for residential customers.”

Staff also was instructed to modify its order approving the facility “to allow only for operation of a natural gas facility at the Kemper Project location.”

The PSC’s actions deal a major blow for supporters expecting the facility would prove the economic viability of “clean” coal technology. Last year, the Kemper project achieved a series of milestones, producing its first syngas and then using that syngas — combined with natural gas — to generate electricity.

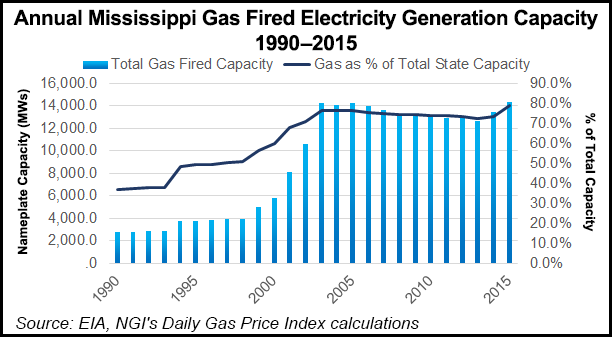

But Southern CEO Tom Fanning admitted during a recent quarterly earnings call that competition from relatively inexpensive and abundant natural gas has changed the economic equation for the Kemper project.

“Getting to this point, we have certainly taken our lumps on this project, but we have delivered what was originally certificated in 2008,” Fanning said in response to a question about whether it would be better to just operate the plant as a gas-fired facility.

He said the plant has a “rather large” fixed operations and maintenance cost component. But is it better to run the plant as it was designed and get the benefit of the energy, or run it solely as a gas-fired plant? “That is sort of the question you get to.”

© 2024 Natural Gas Intelligence. All rights reserved.

ISSN © 1532-1231 | ISSN © 2577-9877 | ISSN © 1532-1266 |