View more information about the North American Pipeline Map

Background Information about the Montney Resource Play

Startling exceptions to gloom pervading first-half 2015 corporate statements confirm that a sweet spot — where rich resources compensate for poor prices — is emerging in Western Canada’s endowment of natural gas steeped in liquid byproducts.

Seven Generations Energy Ltd. scored growth of 117% in oil production, 172% in gas liquids, 129% in gas and 20% in revenue. Painted Pony Petroleum Ltd. posted output gains of 41% in gas and 9% in liquids, plus its first oil production.

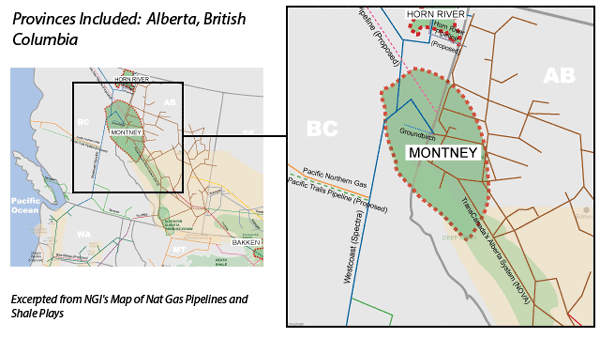

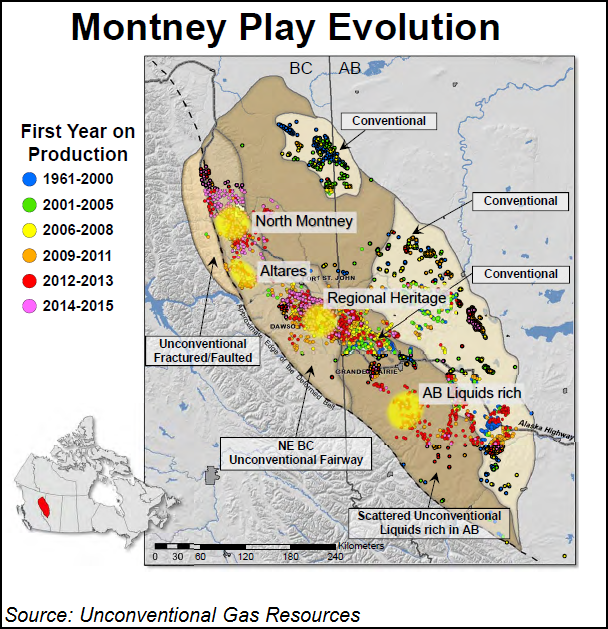

Both companies focus on a geological formation known as the Montney Shale. The structure carpets a 130,000-square-kilometer (52,000-square-mile) region that straddles the border between northern Alberta and British Columbia (BC). Seven Generations works in Alberta. Painted Pony is active in BC. Although a remote frontier by standards of the urban population in Canada and the Lower 48 United States, the area is the most accessible shale or tight gas, liquids and oil zone on the northwestern fringe of the industry.

The region is within vigorous one-day drives on paved roads from the Alberta capital of Edmonton. Lying at varying depths, the thickness of the resource-soaked geological carpet is 100-300 meters (328-984 feet).

The formation spans a region where conventional vertical drilling, pipelines and processing plants have been well established since the 1950s. The territory includes Canada’s latest homestead farming frontier and three northern service and industrial centers: Grande Prairie in Alberta, and Dawson Creek and Fort St. John in BC. The Alaska Highway starts at Dawson Creek

The emerging growth employs Canadian adaptations of horizontal drilling and hydraulic fracturing. Thanks to the advanced technology, Painted Pony’s investor material calls the Montney “one of North America’s premier natural gas resource plays, larger in scope and with similar future potential as the Marcellus play of the northeastern U.S.” The firm adds that the new methods spell access to raw deposits that its experience indicates average 2 Bcf of hydrocarbons per square mile (see Shale Daily, Aug. 17, 2015).

Processing and pipeline firms are building plants and laying conduits, reducing shortages of facilities that have fallen short of field capacity and at times limited producer sales and profits.

AltaGas Ltd. and TransCanada Corp.’s Alberta and BC pipeline network, Nova Gas Transmission Ltd., are each carrying out C$1 billion-plus (US$770 million-plus) growth programs.

TransCanada subsidiary Nova Gas Transmission Ltd. (NGTL) is proposing a C$470 million (US$352 million) addition for production from a rich zone in the Montney geological formation known as Tower Lake (see Shale Daily, Sept. 11, 2015).

In a construction application to the National Energy Board (NEB), NGTL observes that the supply source for its proposed Towerbirch Expansion is only 3.5% of BC’s share in the Montney region, which straddles the BC-Alberta boundary.

But the planned facilities are supported by eight-year contracts to deliver 590 MMcf/d of gas for an international partnership developing a 414-square-kilometer (160-square-mile) spread of Tower Lake drilling rights.

The shale gas sweet spot is west of the southernmost leg of Alaska Highway between Dawson Creek and Fort St. John. The 87-kilometer (52-mile) Towerbirch route parallels the northeastern BC road, then veers east to NGTL’s main network in Alberta.

“The Montney play, which was formerly characterized as tight and uneconomic, has been successfully commercialized with the application of horizontal drilling and multi-stage hydraulic fracturing,” NGTL’s construction application said.

“The Montney formation holds one of the largest unconventional gas resources in North America and is one of the most economic formations in the Western Canada Sedimentary Basin, with production reaching approximately 3 Bcf/d in just a few years.”

The Tower Lake producers are prime drivers of the increasing output. The Towerbirch Expansion gas delivery contracts are held by a venture called the Cutbank Ridge Partnership, owned 60% by Encana Corp. and Japan’s Mitsubishi Corp.

Unlike other big items on the TransCanada-NGTL growth agenda, the Towerbirch line is scheduled for immediate construction to go into service by Nov. 1, 2017 regardless of the fate of BC liquefied natural gas export terminal proposals.

Along with migration of supply development to the Canadian industry’s “near frontier” of BC shale areas, the Towerbirch project highlights rising demand by Alberta thermal oilsands extraction plants.

While aging Alberta wells continue natural depletion, NGTL forecasts that Tower Lake production will quadruple in 10 years by rising to 1.2 Bcf/d as of 2025 from 300 MMcf/d. The compact area already has 9.5 Tcf of reserves recoverable by the current stage of evolving Canadian fracking technology, NGTL said.

Over the same period, total Alberta consumption is projected to climb by nearly 50% to 6.94 Bcf/d from 4.67 Bcf/d.

During 2015-2025 gas purchases by still-growing oilsands operations are forecast to jump by 91% to 3.56 Bcf/d from 1.86 Bcf/d.

Purchased gas as fuel for steam heat-driven production systems accounts for about 70% of bitumen plant fuel consumption recorded by the Alberta Energy Regulator (AER). The total, currently forecast to hit 5.1 Bcf/d in 10 years, also includes gas byproducts of the oilsands process and fuel used by production site power stations.

“Oilsands demand continues to be a strong market,” NGTL said. TransCanada’s western network is also working on facilities additions for northern Alberta projects that began before the current low on the oil price cycle and aim to outlast the slump.

Denver-based Meritage Midstream Services is partnered with Canadian International Oil Corp., a Calgary-based firm owned by an array of private capital investment houses, on a pipeline system near Grande Prairie designed eventually to carry up to 225 MMcf/d of gas and 10,000 b/d of liquids.

The Canadian industry is voting with its drilling rigs in favor of continuing development. During the first 40 weeks of 2015, a scorecard kept by TD Securities Inc. showed nearly 500 horizontal well licenses made the Montney the most popular drilling target. Despite an industry-wide drop of 54%, the Montney total was off by only 5% compared to the same period of 2014.

The activity is making a start on developing astronomical potential documented in a 2013 federal-provincial resource appraisal by the AER, the BC Oil and Gas Commission, the BC Ministry of Natural Gas Development, and the National Energy Board (NEB).

In the report’s conservative scenario for most likely “recoverable” or “marketable” reserves, the Montney was rated as holding 449 Tcf of natural gas, 14.9 billion bbl of liquid byproducts and 1.1 billion bbl of oil.

The figures are liable to grow as experience is gained in the deposit, added the appraisal by earth sciences arms of the government agencies. A high-case forecast pegs Montney supplies at 645 Tcf of gas, 21 billion bbl of NGLs and 2.4 billion bbl of oil.

The Montney is the first supply source earmarked for liquefied natural gas (LNG) export terminals proposed on the Pacific Coast of BC. The deposit’s most active developers include the Pacific Northwest LNG project led by Malaysian state energy conglomerate Petronas and its Progress Energy subsidiary in Calgary.

But high-priced overseas destinations are not the only places where Montney gas is forecast to fare well. The NEB’s current Canadian “deliverability” projection, released in June, rates the new northern BC and Alberta output as some of the lowest-cost gas in North America and becoming competitive with Marcellus Shale production. In fact, Credit Suisse estimated in August 2015 that the Montney has NYMEX natural gas breakeven prices between $0.75 and $3.50 per MMbtu, thereby making the Montney one of the most economical producing regions in North America.

A big reason for the favorable increase in well economics has been the adoption of more advanced drilling and completion techniques in the Montney, particularly from operators who have had success in other unconventional formations. For example, Encana noted on its 3Q15 conference call that the industry has been drilling horizontal wells in Montney for more than a decade, but “In the past year, we have doubled the productivity of our wells through increasing frac intensity. As a result, Montney generates returns of greater than 60%.” Murphy Oil also has reported improved performance in the Montney, as a result of lessons learned in the Eagle Ford.

Experience with horizontal drilling and fracking is sharply cutting costs. TransCanada’s Nova, in a facilities construction application to the NEB that draws on confidential industry information, says the full “supply cost” of putting Montney production into the market dropped by nearly 60% to C$2.69 (US$2.07) per MMBtu from C$6.45 (US$4.97)/MMBtu between 2006 and 2013.

Efficiency continues to improve. So far this year alone, Seven Generations reported an 8% reduction in well costs, with average drilling time down to 48-50 days from 60 and fracking operations pared to three to four days from a week.

TransCanada has already constructed the 1 Bcf/d Groundbirch Pipeline to transport gas from the Montney to its NOVA system in Alberta, and has proposed two pipelines that would transport Montney based natural gas to the Canadian West Coast. One is the Prince Rupert Gas Transmission Project, which would move supply from the North Montney near Fort St. John, BC to the planned Pacific Northwest LNG export terminal in Port Edward near Prince Rupert, BC. The other is the 1.7 Bcf/d Coastal GasLink Pipeline Project, which would transport both Montney and Horn River gas to Shell’s planned 12 million ton/year LNG export facility near Kitimat.

Several executives with Canadian Junior E&P companies noted in October 2014 that there is a general lack of processing capacity in the northern Montney, a point TransCanada drove home in its application with the NEB to build the North Montney extension of its Groundbirch Mainline. “It is NGTL’s understanding that Progress Energy and other customers will construct several gas plants or work with current operators to upgrade existing plants,” the company noted in its filing. “Approximately 14 gas plants will be required to process the gas expected to be produced by 2020. The customers are also in discussions with midstream companies to secure the sale and transport of NGLs associated with increased gas production,” For now, however, the presence of Alliance Pipeline lessens the need for additional local processing capacity somewhat, because that pipe hauls unprocessed wet gas down to be processed at the Aux Sable plant in Channahon, Illinois.

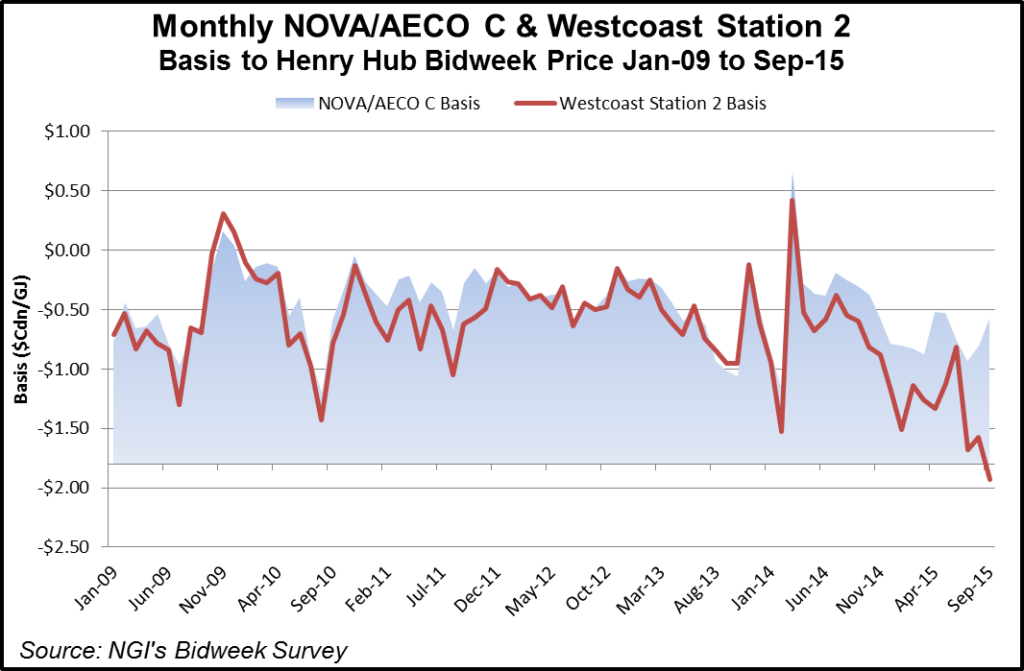

Natural gas pipeline takeaway capacity is also a problem, and although it is being addressed in the longer-term with the projects already mentioned, ongoing restrictions on TransCanada Mainline have forced some curtailments from the Montney at various times in 2015. That has helped crush Station 2 prices, so much so that deals into St. 2 approached zero at several points during the year.

Provinces

Alberta, British Columbia

Pipelines

Natural Gas: Alliance, Coastal Gas Link (proposed), NGTL Merrick Mainline (proposed), NGTL North Montney (proposed), Prince Rupert Gas Transmission (proposed), Spectra

Crude Oil: Alberta Clipper, Energy East, Northern Gateway, TransMountain

More information about Shale Plays:

Utica | Permian | Bakken | Tuscaloosa Marine Shale | Haynesville | Rogersville | Arkoma-Woodford | Eastern Canada | Barnett | Cana-Woodford | Eaglebine | Duvernay | Fayettville | Granite Wash | Horn River | Green River Basin | Lower Smackover / Brown Dense Shale | Mississippian Lime | Monterey | Niobrara – DJ Basin | Oklahoma Liquids Play | Marcellus | Eagle Ford | Upper Devonian / Huron | Uinta | San Juan | Power River | Paradox

Shale Daily

Shale Daily