E&P | NGI All News Access | NGI The Weekly Gas Market Report | Permian Basin

Delaware Basin Activity Draws More Processing Capacity

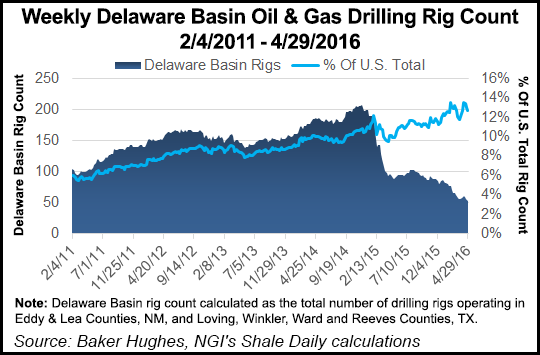

Despite the commodity price downturn, the Permian Basin, and particularly the Delaware sub-basin, have remained attractive to producers, supporting the need for additional natural gas processing in the region.

On Tuesday it was announced that two Delaware Basin facilities had entered service.

Enterprise Products Partners LP has begun operation of a new cryogenic natural gas processing facility in Eddy County, NM. The South Eddy plant, which is supported by long-term, fee-based agreements, has a nameplate capacity of 200 MMcf/d of natural gas processing and is capable of extracting up to 25,000 b/d of natural gas liquids (NGL).

Prior to start-up, much of the natural gas being processed at the plant was flared, shut-in, or blended into a residue pipeline with no NGL upgrade, Enterprise said.

“The South Eddy Plant is a key component of our overall strategy to double Enterprise’s natural gas processing capacity in the Delaware Basin during 2016,” said Jim Teague, CEO of Enterprise’s general partner. “A second cryogenic processing facility we are developing as part of our joint venture at Waha is scheduled to begin service in the third quarter of 2016 and will add another 150 MMcf/d of incremental capacity.”

In association with the plant’s construction, Enterprise constructed approximately 90 miles of high-pressure gathering lines to supply the South Eddy plant. Additionally, the partnership completed a 71-mile extension of its Mid-America Pipeline system, which provides Delaware Basin producers with NGL takeaway capacity and direct access to Enterprise’s integrated network of NGL assets.

“Despite the decrease in rig count nationwide, the Delaware Basin remains very active [see Shale Daily, Feb. 19],” Teague said.

Separately, EagleClaw Midstream Services LLC said it has commissioned its cryogenic Toyah I Natural Gas Processing Plant in Reeves County, TX. It has capacity to process 60 MMcf/d and serves producers in the Permian’s Delaware Basin targeting stacked pay zones including the Upper and Middle Wolfcamp, Bone Spring and Avalon shale formations.

The Toyah I plant is served by 120 miles of gathering pipeline and four field compressor stations.

An 18-mile NGL line connects the Toyah I plant to Lone Star’s West Texas Gateway Pipeline, which transports NGLs to the market center at Mont Belvieu, TX. Toyah I also is connected to Kinder Morgan’s El Paso 1600 pipeline, which has excess capacity available for residue gas, EagleClaw said.

EagleClaw expects to establish an additional connection with Oneok’s WestTex Transmission system, which connects with the Roadrunner Gas Transmission Pipeline. Phase One of Roadrunner is complete and currently serving markets in El Paso, Texas, and Mexico.

EagleClaw also said it has purchased a second cryogenic processing plant with capacity to process 200 MMcf/d. It said it expects to install the Toyah II plant at the same location as customer demand increases.

“Our goal is to stay a step ahead of our customers’ processing needs and provide the optionality they need to move hydrocarbons to the best possible markets,” said EagleClaw CEO Bob Milam.

© 2024 Natural Gas Intelligence. All rights reserved.

ISSN © 2577-9877 | ISSN © 1532-1266 | ISSN © 2158-8023 |